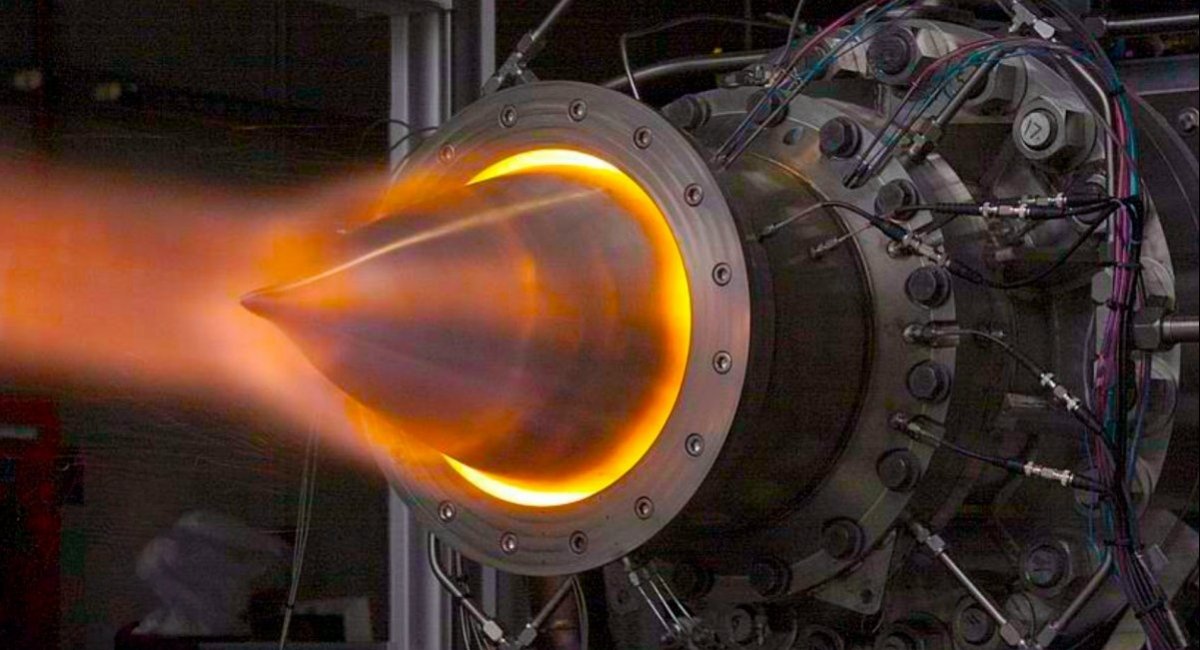

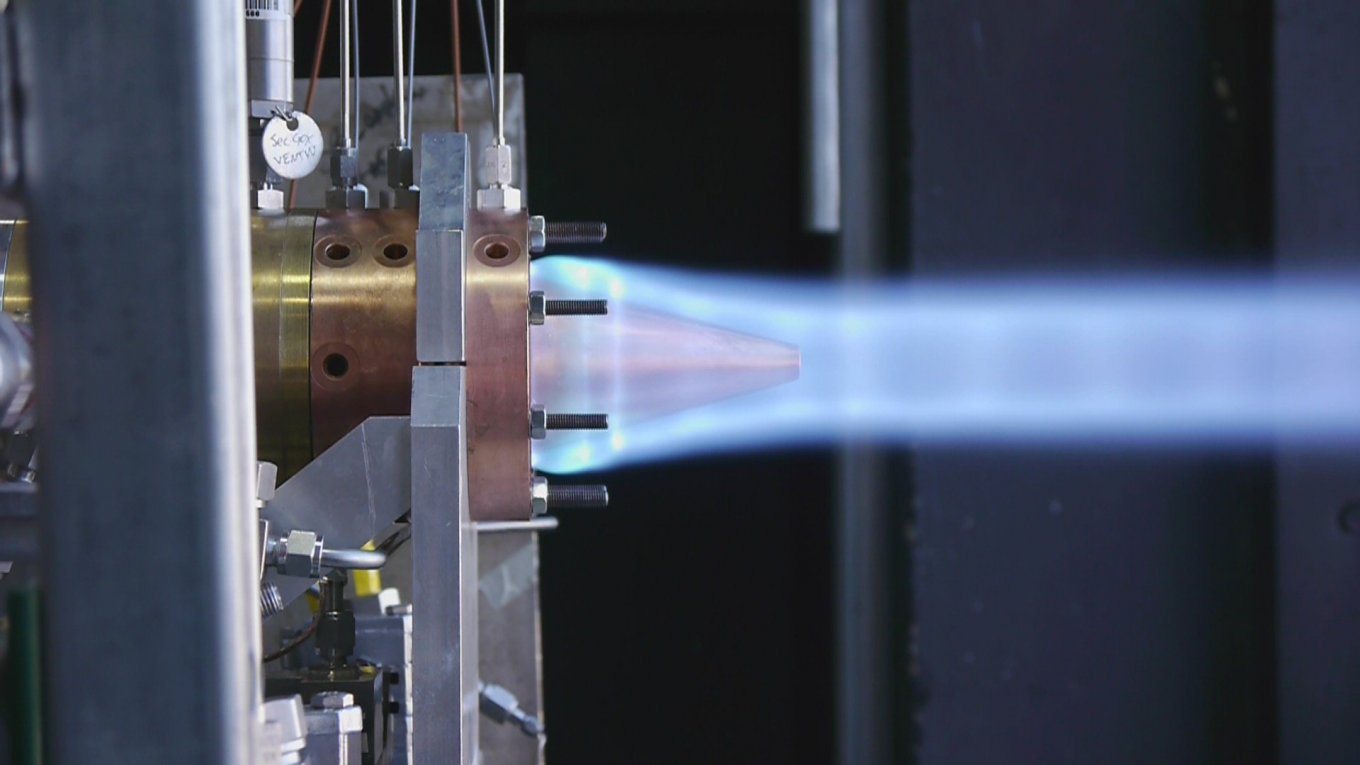

Aircraft engine specialists from GE Aerospace, part of General Electric, have made a bold announcement of achieving a breakthrough in hypersonic engine technologies by revealing successful results of a rig test of their hypersonic dual-mode ramjet with rotating detonation combustion in a supersonic flow stream – hereafter just DMRJ with RDC.

This quite complicated name highlights a very important feature: this hypersonic engine can work at speeds lower than Mach 3, unlike any typical hypersonic airbreathing jet engine, which can only begin operating after the mentioned speed has been reached. Meaning, an aircraft usually has to be accelerated before it can utilize its hypersonic ramjet.

Read more: German Tech Giant Empowers Ukrainian Resilience through Software Solutions and Localization

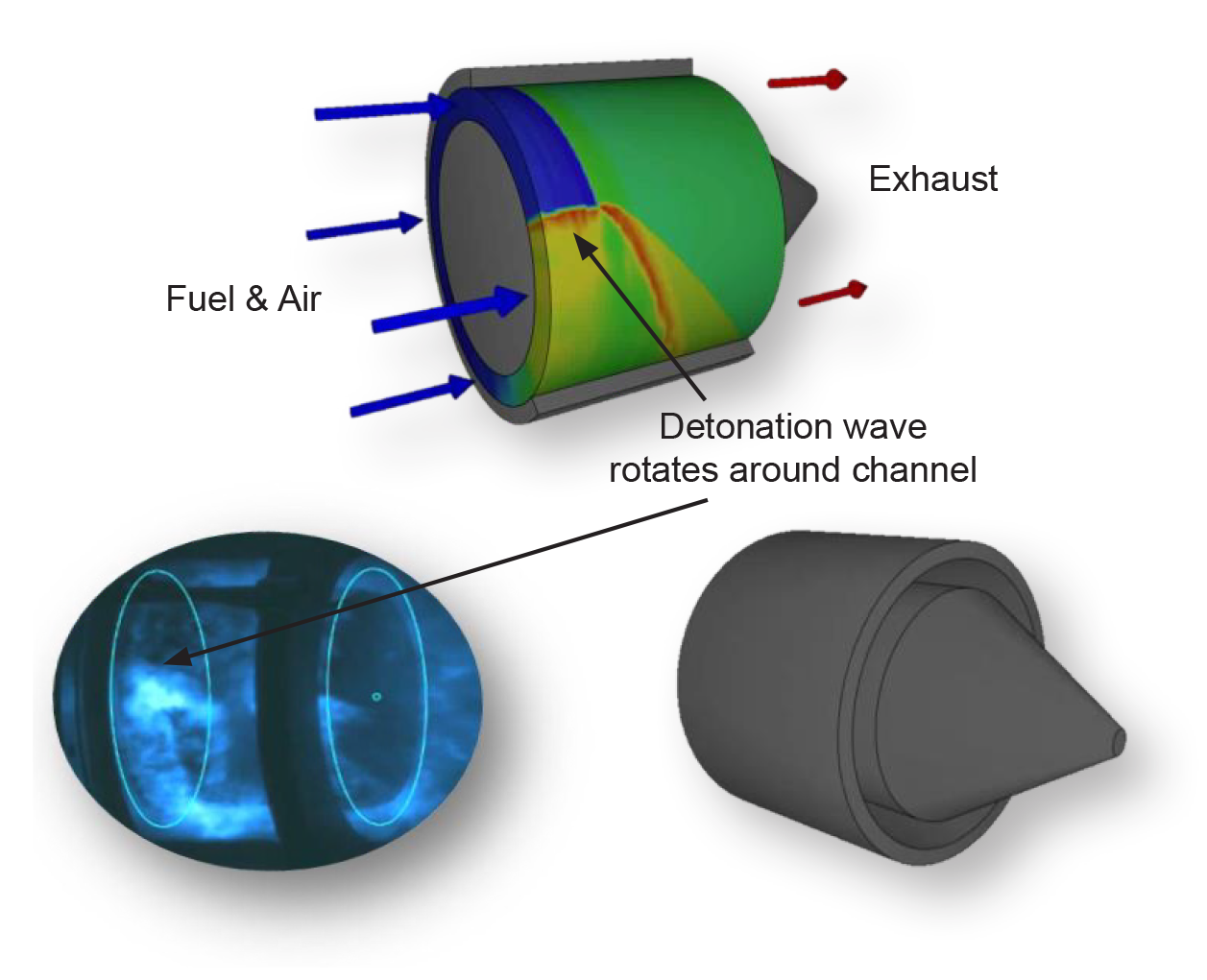

However, the rotating detonation combustion technology creates an opportunity to eliminate this problem. RDC is a type of detonation engine in which detonation waves continuously travel around an annular channel at a speed around Mach 5. Each combustion creates a detonation wave that produces thrust and moving around the channel initiates another combustion, requiring micro-controlled injections of fuel into the channel.

The outcome is an engine with fewer moving parts, lesser weight, and more efficient fuel consumption.

Similar to RDC but using liquid fuel engines were also introduced by other manufacturers, for instance, NASA demonstrated one of their prototypes seeing the technology as a gateway to new opportunities for space exploration.

On the other hand, GE Aerospace managed to combine RDC with a ramjet, adding the capability of operating both below and above Mach 3. Effectively that means hypersonic speeds can be achieved with a single dual-mode engine, eliminating the need for any additional boosters. Moreover, the DMRJ with RDC itself is compact which is crucial for any aerial vehicle.

The combined effect of reaching greater power output and speed, lesser size, and fuel consumption make the engine truly revolutionary, opening the talks of implementing it on airplanes. Because propeller-driven aviation had first struggled to overcome the sound barrier and eventually lost to jet engines, then the latter hit the roadblock of the hypersonic barrier. The DMRJ with RDC is poised to solve this problem and clear the path for aircraft with conceptually new specifications.

This is the result of GE Aerospace working for over ten years in the field of hypersonic speeds, high-temperature composites, silicon carbide electronics, additive manufacturing, and temperature control.

Although it's too fast to celebrate as this achievement is just a rig test, implying the first DMRJ & RDC-powered aircraft is yet to have its maiden flight which can take a while. Nonetheless, it will be an event marking a whole new era in aviation for sure.

Read more: Why russia Needs Helicopter Engines From Egypt, Pakistan, and Brazil