The two companies merged in 2001 to form what is now the State Enterprise “Gas Turbine Research & Production Complex “Zorya”-“Mashproekt” (SE GTRPC “Zorya”-“Mashproekt”), which is an affiliate of the Ukroboronprom State Defense Industries Group. SE GTRPC “Zorya”-“Mashproekt” has won renown far beyond Ukraine for its products for both civilian and military markets. The Company doesn’t rest on its laurels but offers potential customers promising innovative solutions along with already well known products.

Potential and Capacities

Read more: Ukraine reportedly looks to buy 48 Turkish Bayraktar TB2 armed drones

SE GTRPC “Zorya”-“Mashproekt” currently is Ukraine’s top leading developer and supplier of gas-turbine equipment of international quality standards. Employing a workforce of up to 9,000 highly skilled and experienced workers and engineers, the Company has a great experience and a long tradition in the world of marine gas turbines. It is there in Mykolayiv where there were produced the world’s first variable-speed combined gas turbine and gas turbine (COGAG) propulsion system, the M3, and again the world’s first gas-turbine powered anti-submarine warfare ship, the Project 61 Komsomolets of Ukraine, which the Americans nicknamed “Singing Frigate” for the characteristic noise of its gas turbines.

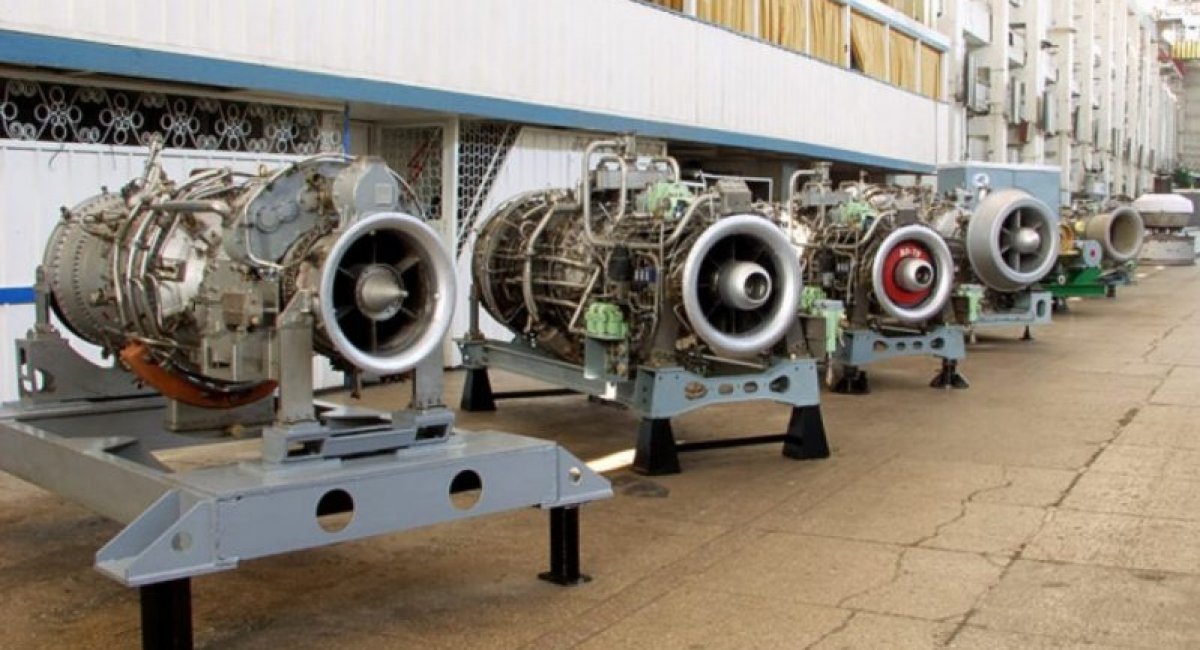

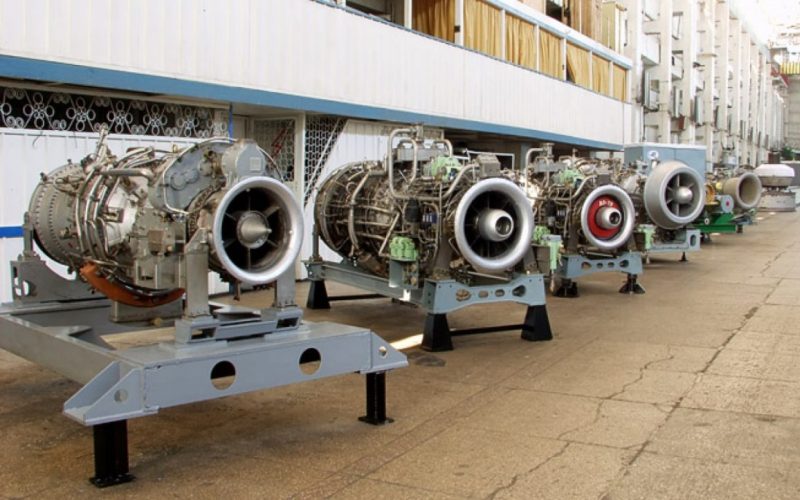

Initially the Company has developed, produced and sold great quantities of the second-gen engines M60 and M8, DT4 with efficiency of 28 percent; COGAG propulsion systems M5, M7 and M9. Afterwards the third-gen engines M75, M70, and M90 for all classes of ships with improved efficiency of 30-35 percent entered in service. SE GTRPC “Zorya”-“Mashproekt” pioneered the use of new structural materials, such as ceramics and compounds, capable to withstand higher temperatures, contributed into development and production of internally cooled turbine blades, and thus resulting in a substantial increase in service life of the GTE in the whole. In 1990s SE GTRPC “Zorya”-“Mashproekt” developed, the fourth-gen GTEs M80 and DN70 having efficiency of 36-37-percent. The Company is also the developer of the gas turbine propulsion systems GTU M21 for missile cruisers, the M16 for hydrofoil craft and the M35 for large hovercraft.

Overall in 1990, up to 65 percent of the surface ships in the Soviet Navy’s inventory were equipped with SE GTRPC “Zorya”-“Mashproekt” GTEs that combined amounted to about 35 percent and 30 percent of the global gas turbine fleet in terms of aggregate power and the number of gas-turbine powered ships, respectively.

Collaborations

The Company has so far developed and produced over three dozen varied types of propulsion gas turbine engines for propulsion of surface ships and craft, including hydrofoils and hovercraft. SE GTRPC “Zorya”-“Mashproekt” GTEs, which make up to 25 percent of the world’s gas turbine fleet, equip ships and craft that are in service with or fielded by the naval forces of a wide-raging set of countries that include: (1) India (Delhi, Kolkata and Rajput classes of destroyers; Talwar classes of frigates; Veer-class corvettes); (2) Bulgaria (Lightning-class corvettes); (3) Greece (Bison-class light landing craft air cushion (LLCAC) vehicles); (4) the Russian Federation (Atlant-class missile cruisers, Berkut-B and Frigate classes of guided missile cruisers; Burevestnik and Gepard classes of cruisers; Bison-class LLCAC vehicles; Lightning-class corvettes; Sivuch-class missile corvettes); Ukraine (Hetman Sahaidachny Frigate); Poland (Warsaw-class destroyer, Lightning-class corvettes), Romania (Lightning-class corvettes), Vietnam (Gepard-class frigates, Lightning-class corvettes), China (Lanzhou-class destroyers, Bison-class LLCAC vehicles) and the USA (Roy M.Wheat Naval Auxiliary).

India is the largest export customer for Zorya-Mashproekt marine GTEs. Few know that the Indian Navy was the first to place an order for GTEs from Zorya-Mashproekt after Ukraine regained its independence in 1991 and it has accounted for approximately 30 percent of the Company’s sales every year since 2009. Presently in the city of Vishakhapatnam is established the repair base EKSILA dealing with the repair of GTEs manufactured by SE GTRPC “Zorya”-“Mashproekt”.

SE GTRPC “Zorya”-“Mashproekt” signed in New Delhi on September 12, 2019 several contracts to sell to the Indian Navy a large quantity of gas turbine equipment, including GTEs, reduction gears and replacement parts kits for many varying classes of naval ships. The contracts furthermore include a gas turbine propulsion system operator training program along with an Engineering Support Package.

On the other hand Goa Shipyard in India shall localize licensed building of the frigates Project 11356. Mentioned frigates will have modernized GTU manufactured by SE GTRPC “Zorya”-“Mashproekt”.

China too has a history of relations with the Ukrainian Company. PRC’s Navy previously selected U.S.-made GTEs LM2500 for its destroyers, but after the U.S. had imposed an embargo on exports of gas turbine engines, Beijing bought from Ukraine ten UGT25000 GTEs along with a full set of relevant engineering documentation and technical manuals under the contract for localization.

The UGT25000 was then reverse engineered by China to produce their own variant, the QC280 featuring an improved performance (achieved by using UGT25000 technology solutions among other things) and an increased power rating of 30,000 kW. The QC280 is designed for integration to China’s new Type 055 (Nanchang-class) heavy guided missile destroyer with displacement of up to 12,000 tons – the PLA Navy’s largest ship in this class. The QC280 is now 95 percent produced locally in China.

Ukraine was during 2013-14 exporting Bison-class LLCAC vehicles (Ukrainian-designed follow-up to the Project 232.2 “Zubr” air-cushioned hovercraft) to China. Relevant contracts made provisions that Ukraine would also supply spare engines and replacement parts and provide maintenance and repair services for those vehicles. Simultaneously, China received the full set of engineering documentation and technical manuals for the Bison landing craft air-cushioned hovercraft vehicle. The first Bison had been shipped to China in April 2013, followed by the second one on March 1, 2014, days before the Ukrainian peninsula of Crimea was illegally annexed by Russia. Both of the vehicles, built in Morye Shipyard (Feodosia, Crimea), have already entered service with the PLA’s Navy, while construction of the other two vessels is progressing with technical support from Ukraine.

The PLA’s Navy wants a fleet of 10-15 air-cushioned hovercraft, with Ukraine hoping to supply marine GTEs for the vehicles. Given that China is building a domestic capacity for GTE production, the country may in the future begin to build the engines under license or even become a fully independent producer.

At an earlier time in 2001 Ukraine exported one Bison-class LLCAC vehicle with a Ukrainian-produced GTE to Greece, a NATO member.

Overall, the Company has produced and sold over 2,500 units of marine GTEs along with several thousand reduction gears, which provide power for a combined fleet of 600 warships in 20 navies worldwide.

The Company continues its work on the design of new types and models of marine gas turbine engines.

New products on offer

Zorya-Mashproekt offers GTEs rating from 3 MW to 25 MW for integration with propulsion systems on all types of both naval and commercial vessels. Zorya-Mashproekt GTEs are renowned for operational robustness and reliability, long service life, economy of use, low size and weight that all meet the stringent standards required in naval and commercial ship engine building. The Company has begun testing a prototype of its new GTE rated at 32-35 MW, which was under development from 2011 to April 2019 and is claimed to be the world’s unique type. The new GTE is being developed in four configurations, one for use in the power generation industry as a mechanical drive for electricity generators; the second for use in natural gas pipeline nets as a mechanical drive for natural gas compressors, while the two others are designed for use as part of marine propulsion plants.

The Company is of the view that the employment of these GTEs in electricity distribution systems will increase operational flexibility and reliability of Ukraine’s national power system, will bolster the country’s energy self-sufficiency and will provide sustained business for Zorya-Mashproekt.

The new GTE is no worse in performance than international-brand counterparts and can well compete with them in export markets.

In view of this and of the practical experience and expertise the Company has in creating effective, efficient and reliable GTEs for different uses, SE “Zorya-Mashproekt” holds a substantial potential for developing cooperation and synergies with potential customers in creating and bringing to market world-class marine gas turbine engines, marine reduction gears and complete propulsion systems for propulsion of all types of ships and craft.

Read more: UK destroyer Dragon enters port of Odesa