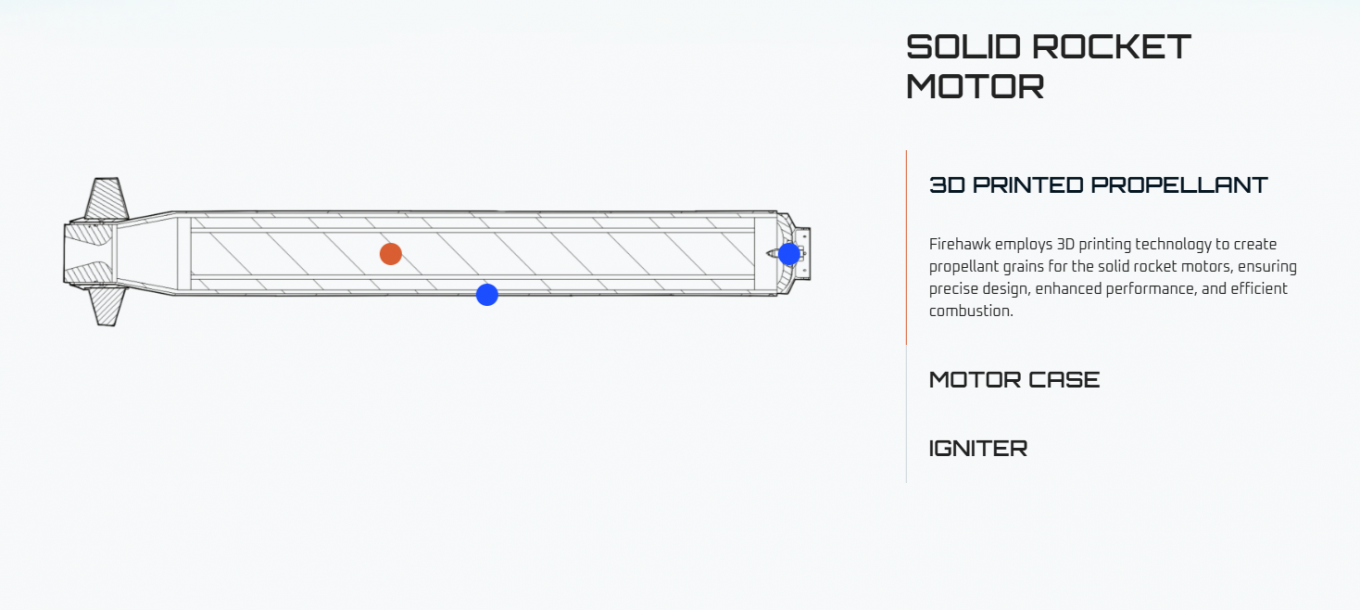

Recently U.S. company Firehawk Aerospace tested solid-rocket motors for the FGM-148 Javelin ATGM and the FIM-92 Stinger MANPADS and the propellant for those motors was 3D-printed.

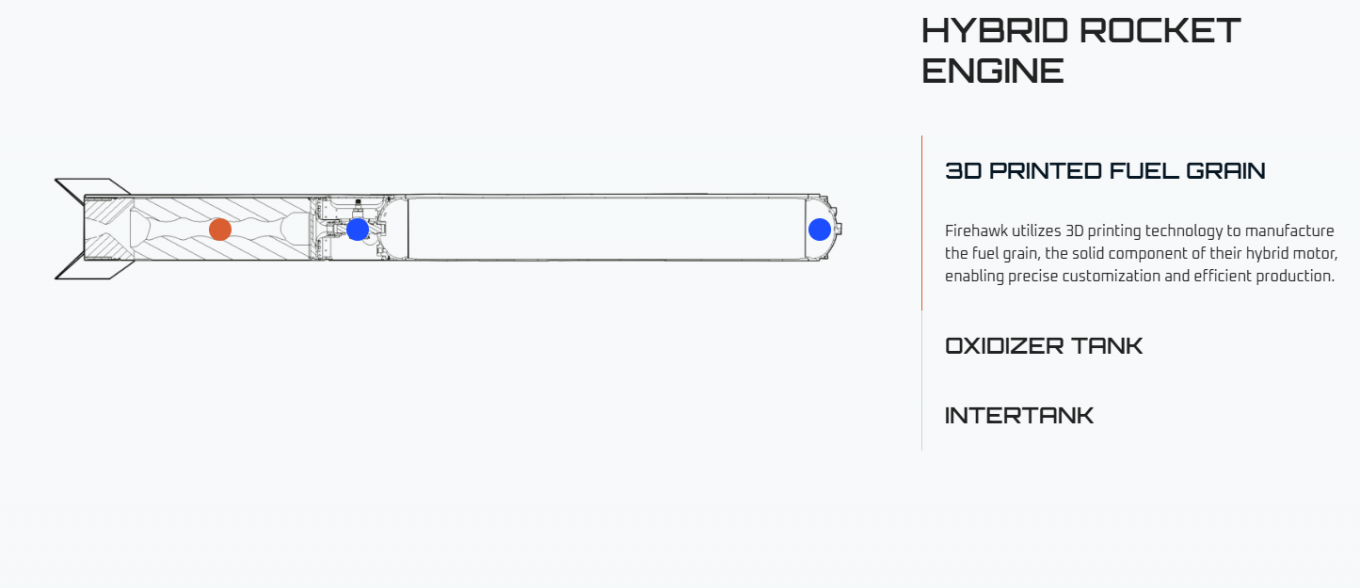

Those tests completed the third and final phase of an SBIR contract with the Army Applications Laboratory (AAL). The contract also covered flight tests of a hybrid rocket system earlier this year.

Read more: U.S. Considers Business Jets as Tanker Aircraft — Could It Work in Ukraine?

3D printing of solid propellant brings many advantages. The biggest is probably a drastic shortening of the motor production cycle. Normally, liquid propellant ingredients are cast into the motor and then left to cure and harden. That process typically takes about 15–60 days.

Firehawk has said that by using 3D printing technology they reduced the production cycle to 3–6 hours a virtually revolutionary speedup for the field. This was made possible by using special thermoplastics as feedstock instead of the thermosetting polymers usually employed.

In the printing process the feedstock is heated before exiting the nozzle so it flows, and it solidifies almost immediately after deposition. A natural question is whether the propellant might ignite during the heating step; the company says it has found a way to protect ammonium perchlorate from decomposition during printing.

Overall, the technology could significantly increase manufacture rates of solid motors for a wide range of rockets from Javelin and Stinger up to GMLRS, which Firehawk has already tested, and even for rocket-assisted artillery projectiles.

Firehawk's portfolio includes not only conventional solid motors but also novel hybrid designs that combine also liquid propulsion elements. In one concept a small solid motor is used initially, while a large oxidizer tank is installed for later injection into the combustion chamber during operation. That architecture potentially allows more flexible thrust control and multi-mode operation.

The company recently raised $60 million from the defence tech fund Presto Tech Horizons. The investment is intended to strengthen Europes ability to produce critical components for the ammunition supply chain.

Read more: 50 Years of Effort: India's Long Road to a Homegrown Aircraft Engine