The Financial Times edition devoted the article to the problems currently taking place in the work of the US military industry. In short, the picture looks like this.

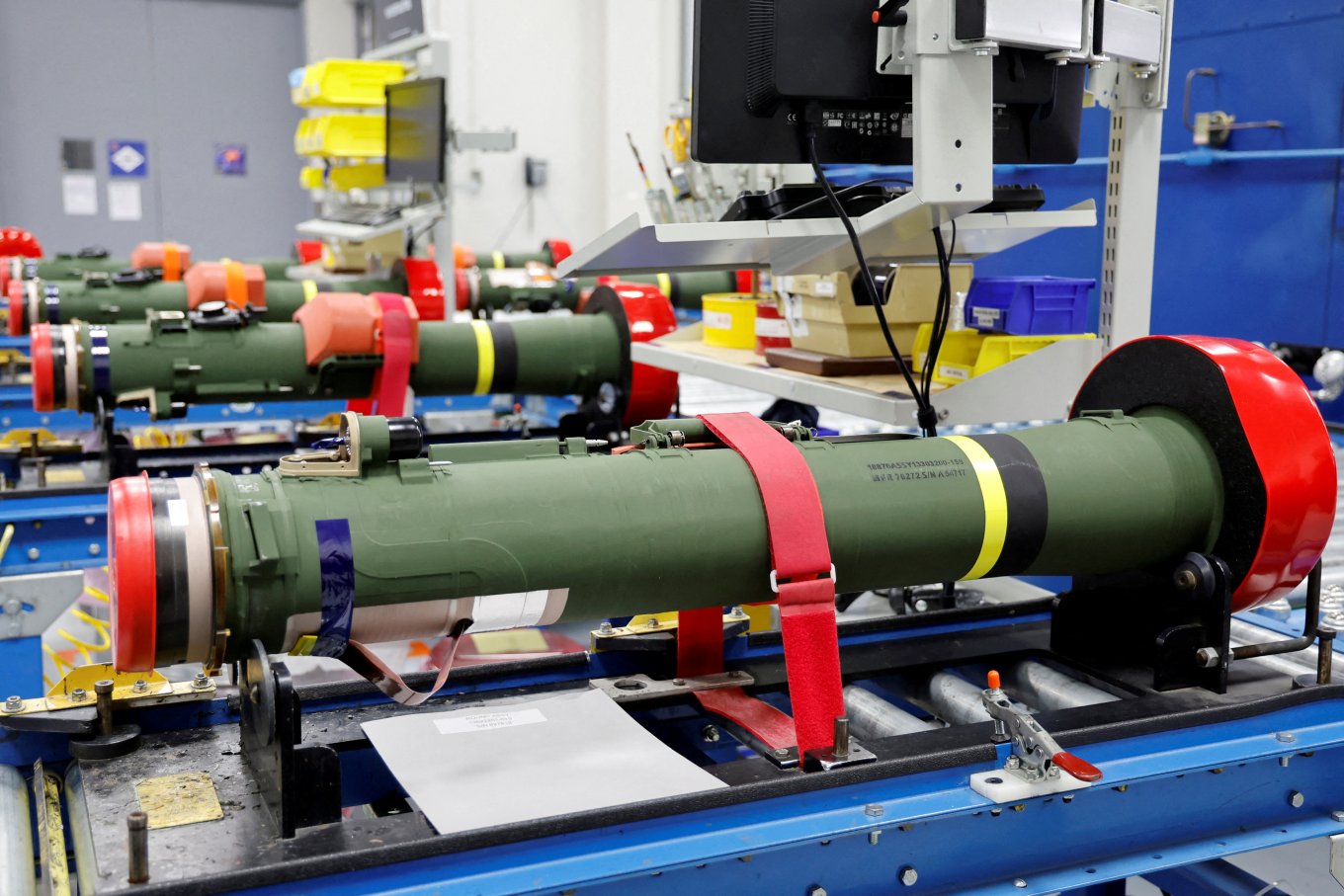

On the one hand, for the past several months, the American defense industry has been working in three shifts with full loading of all production capacities. At the same time, the management of American defense corporations does not spare money for capital investments, and this gives its positive result: for example, over the past year, the production volume of M142 HIMARS launchers increased from 48 to 60 units, the production volume of FGM-148 Javelin missiles - from 2,100 to 4000 units. But at the same time, even such work rates are not enough even to cover the stockpiles of weapons already transferred to Ukraine. Not to mention the option when the USA will have to fight directly against russia.

Read more: Factory For the Production of Kamikaze Drones In russia: 6,000 Shaheds And a New Drone to Create Air Defense Problems

As the authors of the FT explain, the main problem of the American defense industry at the moment is actually a small number of contractors who could scale production accordingly. If in the 1990s, the US military industry had more than 50 main contractors to fulfill Pentagon orders, now there are only five. However, dozens of smaller subcontractors depend on the stability of their work.

As an illustration, for over the past three fiscal years, Lockheed Martin had at least 110 subcontractors for M142 HIMARS launchers and at least 60 GMLRS subcontractors, and quite often the same companies could be involved for both programs. In order to even just maintain their "tree of subcontractors", American defense corporations need stable orders from the Pentagon, calculated for at least several years in advance. But now the US military industry cannot boast of such.

Moreover, the lack of long-term orders from the US Ministry of Defense essentially restrains the expansion of production in the American defense industry. And here we are talking not only about the construction of new production facilities, but also about scaling up the production of components that are needed "here and now". For example, for the FGM-148 Javelin missile, no less than 200 different microcircuits are needed, for the GMLRS it is by no means less.

To make more missiles, the US defense industry needs more rocket engines. And here the "bottleneck" is the limited capacity of the Raytheon Corporation, essentially the only manufacturer of such components in the USA.

Read more: The Number of Leopard 1, Which Can Be Transferred to Ukraine from Industrial Stocks, Was Named In Germany