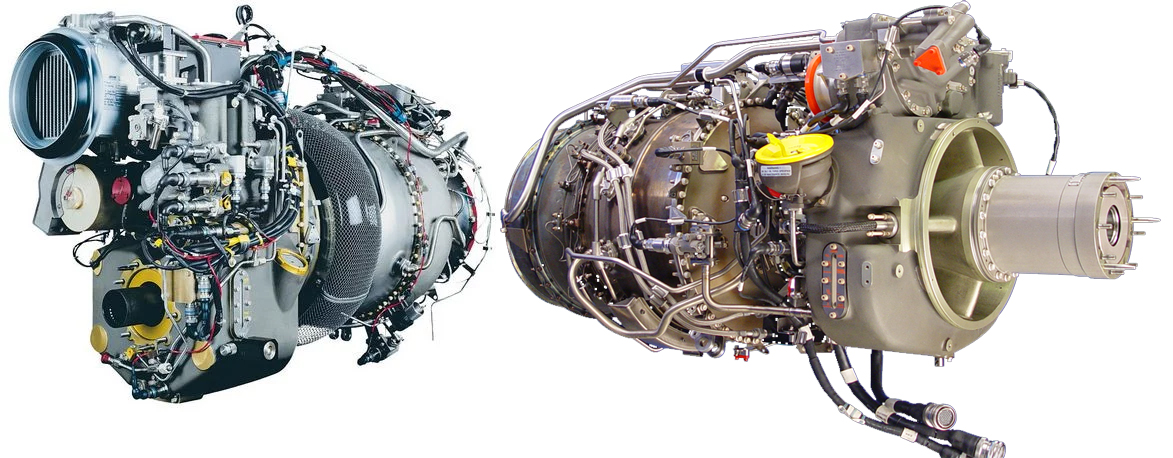

French Safran and German MTU Aero Engines have announced creation of a new joint enterprise that will produce the new helicopter engine for the Next Generation Rotorcraft Technologies project initiated by multiple European countries.

Worth noting, Safran and MTU Aero Engines are both major players in the world's engine production market, quite often they partnered with other giants, including Pratt & Whitney, General Electric, and Rolls-Royce. When it comes to helicopter engines specifically, we should take note of their participation in the creation of the MTR390 for the Tiger attack helicopter, the RTM322 for the NH90 multi-role chopper, and a number of other rotorcraft for AgustaWestland.

Read more: Hensoldt Supplies Airborne Missile Protection System to Ukraine, Enhancing Helicopter Defense Capabilities

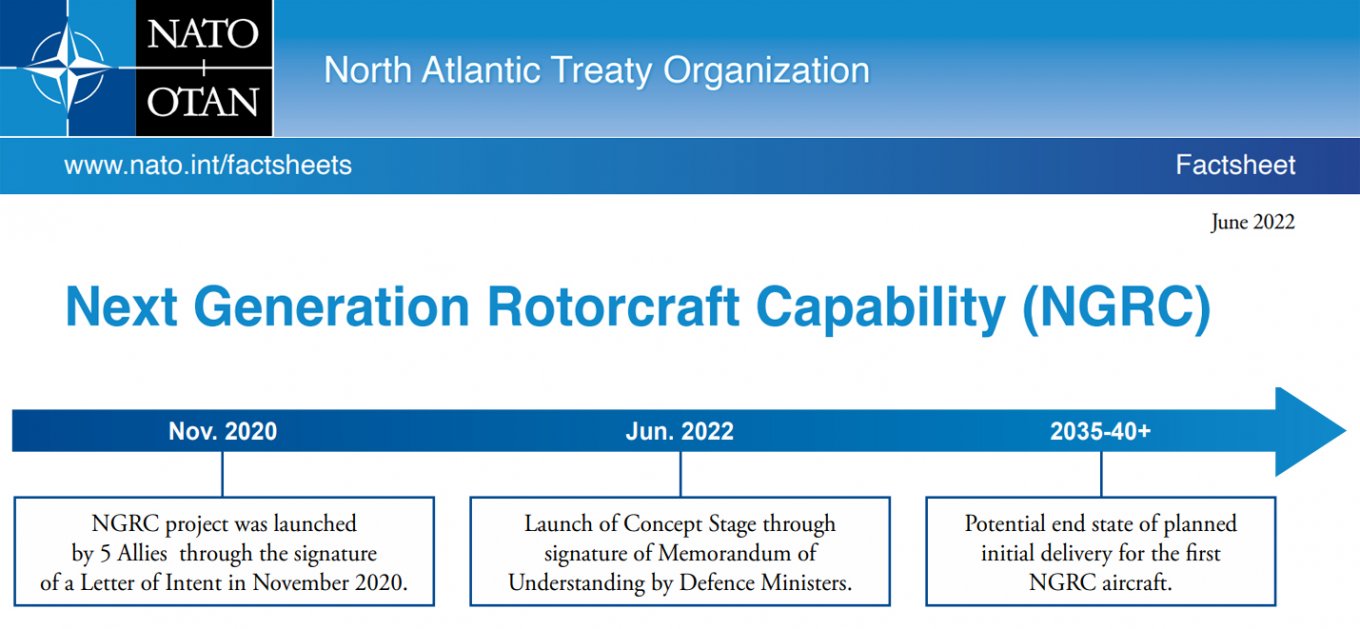

Despite these companies having quite the competence in this field, the announced timespan needed for the production of a new generation helicopter engine is indeed stunning. According to Breaking Defense, during the Paris Air Show 2023, the companies' representatives said only the preliminary stage of technology development is estimated to be done in 2025 to 2029. The main part of the project only starts in 2030.

Taking into consideration the earlier announced terms for the Next Generation Rotorcraft Capability, the new engine must be ready by 2035 or even 2040. In other words, the entire development will take 10 to 15 years.

The NGRC project seeks to create new rotorcraft for the replacement of the entire current helicopter park of six countries in the European segment of NATO: France, Germany, Greece, Italy, the Netherlands, and the United Kingdom. The official fact sheet mentions that the new helicopter engine would utilize "the latest technology on the market" looking toward hybrid and electric propulsion.

On a side note from Defense Express, despite how it may sound, the main point about transitioning to hybrid technologies has little to do with ecological issues, in fact, it means high energy output provided by an electrical power supply, increasing the wattage and service life of the power unit in general. In the context of military application, it also makes cranking up the power unit much quicker and lessens the detection factors compared to when a traditional heat engine is used.

Read more: Russian Reserves of Helicopters: Weapon Capabilities and Production Constraints of Mi-24, Mi-35M and Ka-52 Aircraft