Defense Express traditionally reviews the performance of the defense-industrial complex on the last day of the year for our Ukrainian-speaking audience. However, this time let's talk about the defense industries of NATO countries and the challenges they faced since the outbreak of the russian war of aggression.

This discussion is all the more important because the integration of the Ukrainian military-industrial complex with the Western one has commenced. Also, with Rheinmetall's, BAE Systems' entry into Ukraine, and plans for joint production of ASCOD with General Dynamics, Ukraine has finally broken free from decades of self-imposed defense-industrial isolationism, and thus should be viewed within the framework of the global arms market.

Read more: Defense Express’ Annual Review: the Evolving Landscape of Warfare in Ukraine

Phantom Pains from the Cold War

The year 2023 began with hope that partners would fully equip Ukraine with necessary weapons for the recapture of territories occupied by russia. After talks about the escalation and sending only Soviet-type armored vehicles, a breakthrough occurred in January 2023. Ukraine initiated plans to equip a Leopard 2 tank brigade, expecting at least 84 vehicles provided by partners. To achieve that, the so-called "tank coalition" had to be proactively expanded, and acting members encouraged to give more vehicles.

However, by the summer of 2023, forming a Leopard 2 brigade failed. Despite the total commitment reaching 85 tanks, 14 restored Leopard 2A4s from the Netherlands and Denmark would arrive only in Q1 2024. Refurbishment of these tanks is taking over 8 months.

To put this in the context, in the 1980s, the idea of the German defense industry taking a whole 8 months to repair 14 tanks would have been inconceivable. At that time, the defense industry of West Germany alone produced an average of 300 Leopard 2A4s per year, reaching a record of 450 vehicles in 12 months. Yet, today, the armored industry in united Germany estimates 8 years to produce 72 tanks for Norway and 5 to 7 years to modernize 50 tanks for Austria.

Why this became possible is explained by the reduction in defense spending in NATO after the end of the Cold War. As any other branch, the defense industry follows the rules of the market economy: no orders, hence less production. While the manufacturers were stopping the assembly lines, the governments methodically reduced the number of military personnel in their respective armies — two trends occurring over the last 30 years.

To keep weapon production profitable, weapon prices surged. For example, the Leopard 2A4, costing approximately $1.3 million in the 1980s, now costs about $3.6 million. The Leopard 2A8, even for the Bundeswehr, comes at over $32 million.

True, the technological level of these two tanks is completely different, however, in the 1980s the Leopard 2A4 was considered no less high-tech and advanced than the Leopard 2A8 is now. It's just that the price has skyrocketed due to the laws of the market economy but conceptually the tank and its manufacturer KMW have not changed.

Therefore, reminiscing of former production capacities and prices is akin to phantom pains from the Cold War era. This trend is not unique to Europe but also observed in the United States, where the industry produced 75 M1 Abrams tanks monthly in the 1980s, reducing to only 12 today.

The "Ramping Up" Problem

Currently, a painful process is unfolding, demanding not just production renewal but expanding it to make up for 30 years of hiatus. This occurs in the context of a post-industrial economy, where the heavy and chemical industries — the very foundation of the defense-industrial complex — have also undergone significant reductions in NATO countries.

During WWII, industrial countries could simply switch industries from civilian to military production. In August 1940, Chrysler started building the first tank factory in the United States, the Detroit Arsenal. Eight months later, even before its official opening, it already rolled out its first newly-made tank. Throughout the war, the factory produced over 22,000 tanks — a quarter of all American tanks made then.

On the other hand, many modern countries in the West are no longer capable of repeating the same "trick" because industry always works in a triangle: money, people, and resources — the latter including everything from raw materials to machine tools.

The problem is, renewing production using outdated methods from the mid-20th century almost a hundred years later is difficult to pull off.

Let's say, if we want to set up a robotic conveyor that will assemble tanks in a 24/7 mode, we'll need a commission from the customer worth the effort and investment, and it must be a long-term one, for decades to come. Because, once again, the market rules the industry.

What we saw in 2023 is that so far the West has directed insufficient efforts to devise a long-term vision

Paradigm Shift

Because currently, NATO countries are not even developing, but working on conceptual sketches of those weapons and systems that are supposed to replace the existing ones somewhen in the 2040s. They are arguing whether a new generation main battle tank should be or pan-European a separate German one, while several projects of sixth generation fighters are competing with each other.

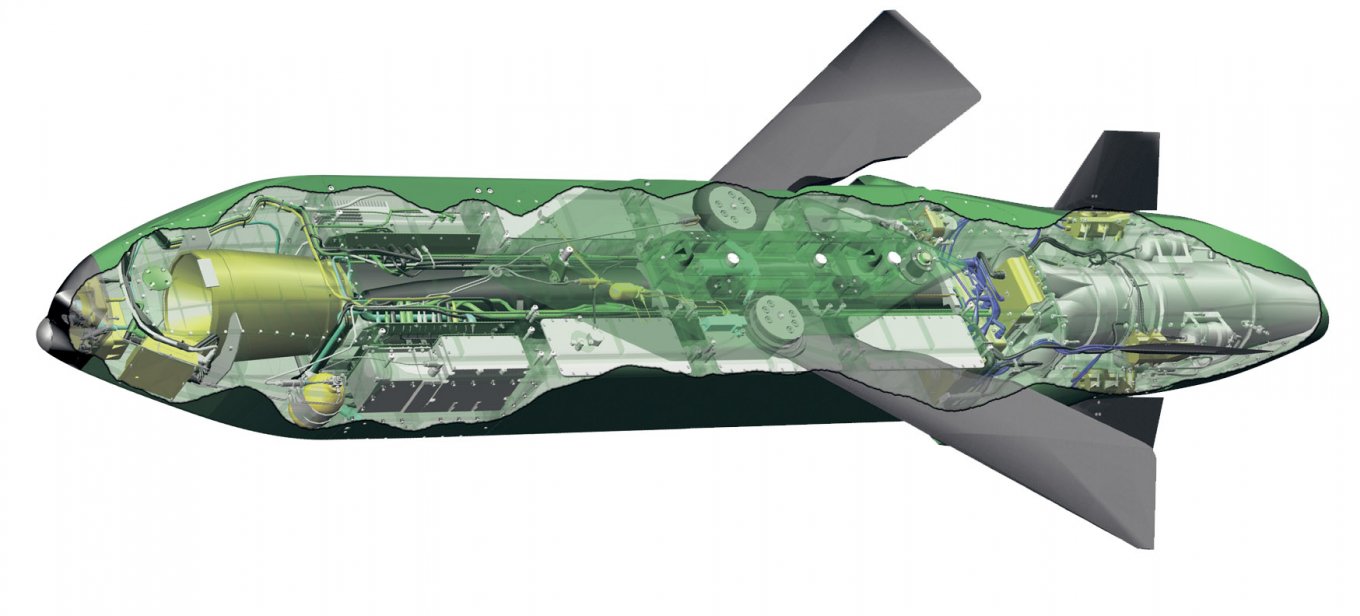

But all these sketches are aimed for long-term development, in the concept of being "few and expensive." On the flip side, it is not that simple to renew the production of old weapons, the situation evolving around German Taurus cruise missiles provides a great example of that.

When MBDA Deutschland was asked to restart the production of this missile, the company declared it was ready to commit but it needed to integrate "new technical advances" in order to"preserve the users' capabilities over the next decade."

In other words, instead of producing a ready-made solution, they want to take the time and money to develop an updated version that will have to undergo testing, enter pilot production, and only then proceed to a full-fledged mass production, probably somewhere in the 2030s.

Although this may well be related to the fact that the components of this missile used for assembly in previous generations just no longer exist so the weapon still needs to be reworked with that in mind. The same thing happened with the Stinger MANPADS — for the renewal of production of this surface-to-air missile, the American factories had to invite retirees back to work.

The only way out of this situation is through a paradigm shift. Defense industries in NATO countries should follow the example from Ukraine, which reduced the time to license and adopt new defense products from years to weeks. Focus on solutions already in civilian market serial production, usable in arms making. Depart from the "few and expensive" concept in favor of simpler systems with lower costs and shorter technological production cycles.

After all, just like Richard Barrons, ex-chief of the Joint Forces Command of the UK Armed Forces, said when speaking to state and business representatives from NATO countries at a forum in Lucerne, Switzerland,

"The only way Ukraine wins is if we now mobilize our industry and our will behind that. And do not tell me it's unaffordable, because you represent an economy of 15 trillion euros a year."

Read more: Tanks, IFVs, APVs: What Weaponry Did Ukraine Receive From Allies in 2023? (Part 1)